Cleaner Cotton™ was the registered trademark for cotton fiber grown in SCP's program. An alternative to more expensive and difficult to produce organic, it was grown according to a set of guidelines provided by SCP regarding sustainable growing practices that included disallowing the most toxic chemicals used in California cotton production. Cleaner Cotton™ also utilized biological farming methods as a basis for growing cotton more sustainably.

Presentations to brands on Cleaner Cotton™ practices, fiber and fabrics were conducted by SCP, but the fiber was sold through traditional cotton marketing channels, with a suggested 10-15 cent per pound premium that went directly to the grower.

SCP's farm program brought together a community of family farmers growing cotton in California's Fresno, Madera and Merced counties. With SCP's support and guidance from experts at UC IPM and UC Cooperative Extension, these growers changed the way they farmed by implementing biologically based practices, which protected the land, air and water resources in the region. The fiber that these farmers produced as part of SCP's program was called Cleaner Cotton™. SCP's farm program was generously supported for many years by the clean water funding through the California State Water Resources Control Board.

WHY CLEANER COTTON™ AND NOT ORGANIC?

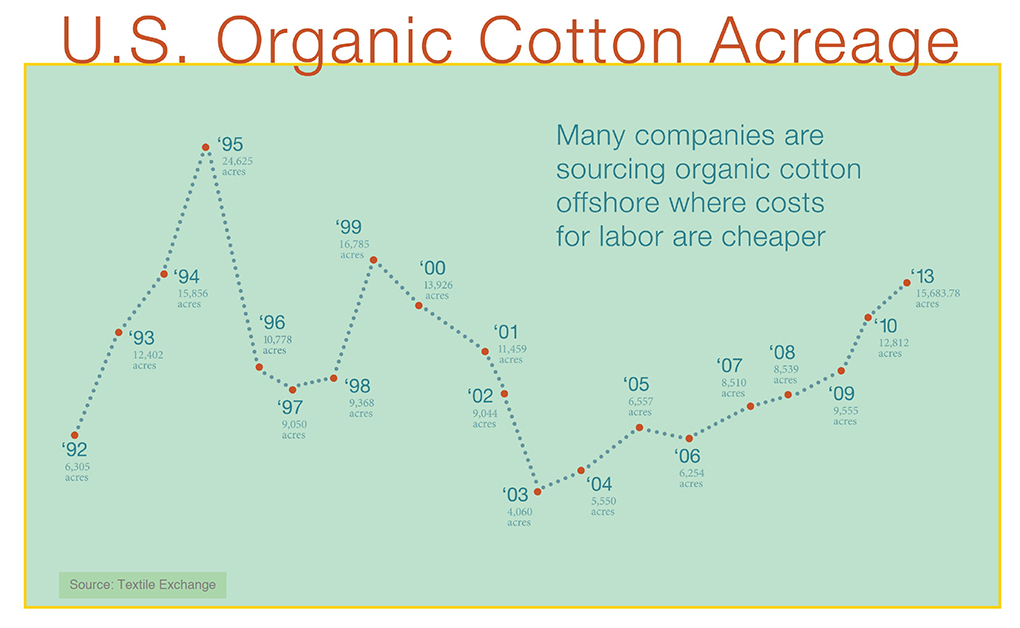

SCP started as an organic cotton organization in 1996. SCP used organic as a tool to transition farmers away from chemically based farming practices and to provide a higher income from the burgeoning sustainable fashion market. (see more on the history of SCP here in ABOUT).

In the late nineteen nineties, NAFTA and China's inclusion in World Trade Organization (WTO) drove US textile production overseas. Organic cotton sourcing also moved overseas to take advantage of lower costs. The cost to grow organic cotton in California was higher than brands were willing to pay. In organic trials that SCP farmers ran, organic cotton fields yielded almost 30% less fiber than conventional fields. To be specific, Cleaner Cotton™, on average, yielded more than 1,250 pounds of cotton per acre compared to average yields of 925 pounds in organic production. Lacking a secure market or a pre planting commitment from brands for their fiber, farmers were unable to risk the lower fiber yields and corresponding reduction in income.

Cleaner Cotton vs Organic

The results of SCP's farming practices are profound

- A Cleaner Cotton™ grower:

- Focused on biologically based practices to manage pests.

- Avoided the most toxic chemicals used in cotton production in California.

- Reduced chemical use from 50-73% over conventionally farmed cotton farmers in the same region (Fresno, Merced and Madera counties).

Because Cleaner Cotton™ maintained fiber yields, it presented less economic risk to the grower and was therefore a more effective tool than organic for converting farmers and acres to biological practices. Overall, this scalability achieved greater reduction in chemicals than the niche of organic cotton. In California, organic cotton generally represents less than 100 acres while Cleaner Cotton™ could be scaled up to meet high demand of millions of pounds of cotton. The higher fiber yield per acre achieved by Cleaner Cotton™ had an additional bonus besides economic viability; it also meant less water was required per pound of Cleaner Cotton™ harvested vs. organic.

CLEANER COTTON™ FIBER...

- Produced high quality fiber, in both Pima (extra long staple length) and Acala (long staple length) varieties.

- Utilized biological farming practices. Click here for more information.

- Eliminated the most toxic chemicals used in conventional cotton cultivation in California, reducing toxicity in our air, soil and watersheds.

- Received a modest premium, paid directly to the farmer to help support management of these practices.

- Was tracked from field to spinner, using the USDA Permanent Bale Identification barcode and data. Click here for more information.

- Cleaner Cotton™ production was local, cleaner, and linked manufacturers, brands and the public, directly with the farmers.

Growers who enrolled with SCP implemented a number of practices that help to reduce the impacts of cotton farming on their region. Below is an example of the types of practices utilized by farmers producing Cleaner Cotton™.

What a conventional farmer would typically do and what a cleaner cotton farmer would do instead:

| Conventional Practice | SCP Cleaner Cotton™ Farming Practice |

| Broad spectrum/higher toxicity chemicals | No spraying or less toxic reduced risk products, pest targeted options |

| Yearly tillage and nitrogen based fertilizer | Reduced tillage and use of compost for some fertilizer |

| Spraying by the calendar | Use of field monitoring reports to note damaging pest buildup and spraying only when economically damaging |

| Weed control sprays on field margins | Use of annual hedgerows on field margins |

| Spraying out natural enemies with broad spectrum chemicals | Use of annual hedgerows, reduced spraying and using reduced risk products help retain and build populations of natural enemies |

| Chemical spraying as a pest protection precaution | Using UC IPM thresholds for deciding if spray is needed |

| Neighboring alfalfa cut without strips | Encouraging neighbors with alfalfa next to cotton to strip cut keeping lygus pest on alfalfa and not cotton |

Cleaner Cotton™ and shifts in production

The late nineteen nineties witnessed the passing of NAFTA (North American Free Trade Agreement) and China joining the WTO (World Trade Organization). US textile sourcing moved overseas where labor costs were lower. Most organic cotton production also shifted to overseas sourcing to achieve price parity with conventional cotton.

California farmers could not compete with these low labor costs and SCP had to question its strategy of using organic cotton as a tool to reduce chemical use in cotton. Brands simply would not pay the cost of organic cotton production in California due to the costs of labor, certification and handling as well farmers having limited products to control pests and diseases that can impact the final fiber product.

Encouraged by SCP farmers like John Teixeira (see Farmers page), who had directly experienced how successful SCP's biological field work was in reducing chemical inputs and maintaining fiber yields, SCP pivoted to promoting the cotton from the field program, and naming it: Cleaner Cotton™.

(Currently under revisions to 2020)